inside the demanding entire world of drilling and solids Management, operational performance hinges to the trustworthiness and overall performance of each element. Amongst the most crucial tend to be the shaker screens, the primary line of defense in eradicating drilled solids from valuable drilling fluid. having said that, sourcing the right screens can generally grow to be a posh puzzle involving mismatched tools, incompatible fluid techniques, and logistical difficulties. This incompatibility won't just lead to frustration; it contributes to enhanced downtime, better operational expenses, and potentially compromised drilling fluid Attributes. consider the aid of locating a single, higher-overall performance display screen Option that seamlessly integrates using your current setup, performs flawlessly throughout various purposes, and simplifies your whole source chain. high quality Drilling tools understands these worries intimately. That's why our VSM300 replacement shaker screens and wholesale Shaker Screens are engineered not only for Extraordinary separation effectiveness and sturdiness, but with universal compatibility at their core. These screens depict additional than simply a ingredient; They're a strategic Alternative created to adapt for your various operational requirements, guaranteeing sleek, uninterrupted general performance where ever and having said that you drill. this information delves in to the multi-faceted compatibility of Premium VSM300 shaker screens and wholesale Shaker Screens, exploring how their layout philosophy addresses the important demands of contemporary drilling functions across machines, fluids, circumstances, industries, and logistics. As a leading Shaker Screens company, we prioritize adaptability to deliver unparalleled benefit.

Table of contents:

Seamless Integration: common Fit throughout main Shaker models

Mastering the combination: Unwavering Performance in Diverse Drilling Fluids

created difficult: trustworthy Solids Regulate in every single Drilling natural environment

further than the Oilfield: Extending large-functionality Separation to New Frontiers

Streamlined Operations: created for Efficiency from Warehouse to Wellsite

Partnering with quality: Your supply for top quality and Reliability

Seamless Integration: Universal healthy throughout Leading Shaker brand names

on the list of most significant operational head aches in solids Management management is navigating the numerous landscape of shale shaker products. unique rigs generally utilize shakers from various producers like Derrick, Swaco, Kemtron, and Other people. Sourcing distinct replacement screens for each product may result in elaborate stock administration, greater procurement overhead, as well as frequent risk of buying the incorrect element, causing high-priced delays.

high quality VSM300 replacement shaker screens are engineered to remove this compatibility bottleneck. Designed with universality in your mind, these screens aspect standardized dimensions and mounting mechanisms meticulously crafted to fit seamlessly on to a wide array of mainstream shale shaker models, such as the Brandt VSM300 Main decks for which These are direct, significant-top quality replacements. This cross-brand name shaker display screen compatibility fundamentally simplifies functions. in lieu of juggling multiple SKUs and supplier associations for different shaker models, operations administrators can standardize on quality screens, streamlining procurement processes and drastically lowering inventory complexity.

Crucially, top quality adheres strictly into the API RP 13C testing and labeling standards. What this means is Each individual screen mesh designation corresponds to the confirmed Slash position and conductance functionality, making certain predictable and reliable separation. When you install a Premium VSM300 substitute shale shaker display screen, you will be setting up a part that fulfills internationally regarded benchmarks. The precision engineering ensures a wonderful healthy with no will need for modifications or substantial changes all through set up, minimizing downtime and eliminating the threats linked to improperly fitting screens, which include solids bypass or display screen destruction. This plug-and-Participate in compatibility translates specifically into operational effectiveness and peace of mind.

Mastering the combination: Unwavering effectiveness in various Drilling Fluids

Drilling fluids tend to be the lifeblood of any drilling operation, but their composition varies noticeably depending on geological formations, environmental regulations, and effectiveness necessities. Operations may possibly switch in between Water-dependent Muds (WBM), Oil-based mostly Muds (OBM), and artificial-Based Muds (SBM), Every single presenting unique issues to shaker display screen integrity. WBMs might be corrosive, OBMs contain intense foundation oils and emulsifiers, and SBMs, while generally far more eco-friendly, even now possess unique chemical properties. Moreover, temperatures downhole and in the surface area can fluctuate considerably.

high quality VSM300 drilling fluid screens are especially made to face up to these various and often harsh chemical environments. The foundation of their resilience lies in the selection of materials. employing higher-strength shaker screen frames, frequently created from robust steel, presents the mandatory structural integrity. additional importantly, the display cloth by itself and the bonding agents applied are preferred for their chemical resistance. Premium employs advanced coating technologies and resources that resist chemical degradation, swelling, or softening when exposed to the advanced chemistries of WBM, OBM, or SBM programs. This will make them an ideal OBM appropriate display Answer, dealing with the demanding mother nature of oil and artificial-dependent fluids with out untimely failure.

This inherent fluid compatibility assures reliable separation overall performance whatever the mud process in use. The screens manage their rigidity and aperture integrity, preventing blinding or plugging even underneath difficult fluid rheologies or large temperatures. This toughness interprets into an extended operational lifespan for each display screen, cutting down the frequency of screen replacements, reducing overall monitor usage prices, and reducing the environmental footprint connected to disposal. Operators can confidently deploy Premium screens across many drilling strategies without the need of worrying about fluid-induced failures, making certain the solids Management screen functionality stays optimum.

Built Tough: trustworthy Solids Management in each and every Drilling natural environment

Drilling operations happen in some of the World's most Serious and assorted environments, from scorching desert landscapes onshore to turbulent deepwater places offshore. Each individual location offers distinctive operational worries. Onshore rigs may well face dust and Serious temperature swings, whilst offshore shaker screen applications have to endure corrosive salt spray, continuous movement, and stringent environmental laws. In addition, modern day drilling normally consists of advanced well profiles, like deep vertical wells, prolonged-achieve drilling (ERD), and higher-stress, superior-temperature (HPHT) situations, all of which put huge stress on solids control equipment.

high quality VSM300 shaker screens are engineered for robustness, demonstrating Extraordinary adaptability throughout these assorted drilling environments. Their structural structure emphasizes rigidity and resilience to resist the powerful vibrations inherent in shale shaker operation. The significant-power body building and protected monitor fabric mounting stop flexing and exhaustion failure, even under significant G-forces produced with the shakers. This structural integrity is crucial in protecting regular display stress, which happens to be essential for successful solids conveyance and fluid throughput.

In demanding ailments like deep wells or HPHT environments, in which drilling fluids generally exhibit better densities and flow premiums, top quality screens sustain their general performance. They proficiently resist the erosive pressure of substantial-velocity fluid and abrasive drilled solids, ensuring trusted separation and defending downstream tools like centrifuges and mud cleaners. Their proven effectiveness extends to unconventional useful resource plays, for example shale fuel and coalbed methane drilling, the place precise solids removal is very important for optimizing drilling fluid Houses and managing great solids loading. no matter whether functioning on the land rig in Texas or a semi-submersible platform during the North Sea, quality screens deliver dependable functionality, contributing drastically to The soundness and effectiveness of your complete drilling fluid circulation program.

further than the Oilfield: Extending superior-efficiency Separation to New Frontiers

even though the oil and gasoline marketplace stays a Key emphasis, the fundamental require for efficient and responsible good-liquid separation extends considerably outside of drilling rigs. Numerous other industries rely on equivalent screening engineering to system slurries, take care of waste streams, and recover precious components. top quality's dedication to quality, sturdiness, and compatibility will make its shaker screens a really adaptable Alternative for these assorted purposes.

take into account the geothermal Electricity sector. Drilling geothermal wells requires circulating fluids to remove rock cuttings, a course of action functionally similar to oil and fuel drilling. top quality screens provide the needed toughness and separation efficiency for these functions. In the mining market, shaker screens may be employed in processing mineral slurries, separating coarse solids from course of action liquids properly and economically. Their robust building handles the often hugely abrasive mother nature of mined components.

Additionally, industrial wastewater cure plants frequently have to have screening methods to get rid of suspended solids before even more processing. high quality screens, with their numerous mesh sizes and sturdy design, can be tailored for Principal screening stages in municipal or industrial effluent treatment. Even in civil engineering projects, which include Horizontal Directional Drilling (HDD) for pipeline or utility set up, managing drilling fluids and getting rid of soil cuttings is crucial, and higher-overall performance shaker screens Engage in an important purpose. top quality's name as a trusted oilfield display screen provider Obviously extends to these adjacent marketplaces, featuring demonstrated technologies that satisfies large requirements for separation precision, operational uptime, and long-expression benefit across a spectrum of strong-liquid separation difficulties.

Streamlined Operations: made for Efficiency from Warehouse to Wellsite

real compatibility extends past the Bodily fit and fluid resistance; it encompasses your read more entire lifecycle in the display screen, from storage and transportation to installation and substitute. Operational efficiency is heavily affected by these logistical aspects, significantly for big-scale drilling contractors or operators running international fleets. Downtime spent wrestling with cumbersome packaging or elaborate set up strategies is downtime that instantly impacts The underside line.

top quality VSM300 shaker screens are built with method-large compatibility in your mind. They're packaged in standardized, strong formats appropriate for Intercontinental shipping and effective warehousing. The packaging is intended to guard the screens all through transit and managing when becoming simply stackable and workable, optimizing Place in containers and storage racks. This attention to element simplifies stock management and guarantees screens arrive at the rig web-site in fantastic affliction.

within the rig ground, efficiency is paramount. quality screens are suitable for relieve of handling and installation. Their development aims for an best balance amongst robustness and weight, letting for easier maneuvering by rig staff. The precise Proportions and standardized mounting interfaces, typically making use of basic wedge or tensioning methods compatible with VSM300 shakers, help speedy display adjustments. This significantly reduces time essential for display alternative, minimizing non-successful time (NPT) and holding the solids Handle procedure operational. for big drilling enterprises centered on maximizing drilling times and minimizing operational interruptions, this logistical and installation compatibility is a crucial benefit, reducing labor expenses and maximizing Over-all job performance.

Partnering with top quality: Your supply for excellent and trustworthiness

selecting the proper shaker monitor includes much more than simply matching a component amount. It demands choosing a part engineered for wide compatibility, Fantastic durability, and steady functionality throughout the complete spectrum of operational variables. high quality VSM300 substitution shaker screens embody this philosophy. as being a committed Shaker Screens manufacturer, quality controls the look, supplies, and manufacturing processes, making certain every single display fulfills stringent top quality specifications and provides on its guarantee of adaptability and trustworthiness.

Our deal with shaker display compatibility – across brands, fluids, circumstances, industries, and logistics – translates into tangible Advantages for our customers: simplified procurement, reduced stock, for a longer period screen lifetime, minimized downtime, and Improved operational effectiveness. regardless if you are running just one rig or a global fleet, operating in conventional oilfields or groundbreaking new energy frontiers, quality delivers a reliable Alternative. We also cater to much larger procurement wants, offering wholesale Shaker Screens options that give Price tag-efficient solutions for stocking and huge-scale functions.

In summary, the obstacle of compatibility in solids Management tools is a big hurdle that may impede performance and enhance expenditures. high quality VSM300 replacement shaker screens instantly address this problem by providing an unparalleled degree of adaptability. Their universal in shape simplifies integration with existing shaker fleets. Their robust building makes certain reputable functionality throughout varied drilling fluids and harsh functioning environments. Their versatility extends their application past conventional oil and gas into a variety of industrial sectors. as well as their style and design optimizes logistics from warehouse storage to rig-flooring set up.buying high quality VSM300 shaker screens is an investment decision in operational certainty and effectiveness. quit wrestling with compatibility challenges and start enduring the main advantages of a truly adaptable, large-effectiveness solids control Option.Speak to Premium Drilling devices today to debate your precise requirements, request a estimate, or learn more regarding how our VSM300 substitute shaker screens can streamline your functions and improve your base line. pick out compatibility, choose performance, pick top quality.

Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Dawn Wells Then & Now!

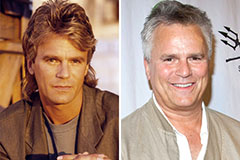

Dawn Wells Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!